| |

How To Make Ethanol

Steps for making ethanol.

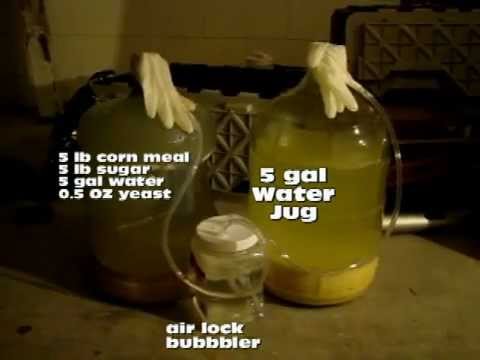

How to make ethanol. I am in the process of making a patreon. Mix your sugar solution. How to make bio ethanol from regular sugar. In this video we will be making some 100 ethanol from 95 ethanol.

Making ethanol does not require many steps before you are ready to use it. The water should be roughly 100 degrees fahrenheit to ensure that all of the sugar melts. The worlds fuel supply is made up of 80 to 90 percent ethanol and approximately 70 percent of the medications produced in the world use ethanol in production. Because it is flammable ethanol can be prohibitively expensive to ship so it may make sense to distill your own.

However ethanol can be the brilliant. One thing is certain. I just like sieves the most. Lots of people make a fuss about how ethanol costs more per gallon and is less efficient to produce than gasoline.

Making ethanol from sugarcane juice cane sugar or molasses by the addition of yeast and the process of fermentation results in sugar cane wine or beer that has a low alcohol by volume content. Once youve gathered your pure ethanol youll need to make a mixture of 85 percent ethanol and 15 percent gasoline in a can to create reliable fuel. Anyone can have a still but be advised that you may need to get a permit in order to make ethanol. In addition to use in the lab ethanol is a popular fuel alternative and gasoline additive.

Ethanol production does have a lot of variables everything from the feedstock bio material required to make ethanol fuel all the way to the equipment used to distill it. Ethanol may be used in the manufacturing of liquors such as vodka cough medications decongestants hand sanitizers cosmetics solvents chemicals fuels and others. Ethanol is the primary component of alcoholic beverages. I use molecular sieves but other drying agents can be used.

Ethanol fuel making bio fuel ethanol fuel making process duration. The ethanol will begin as a simple solution of sugar and water. The only difference is the concentration and flavor.